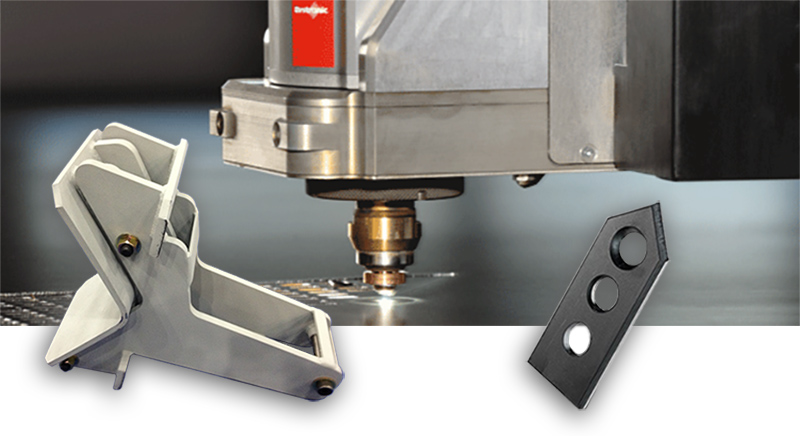

Large Format Laser Cutting from Our Two Flat Bed Lasers

BLM Group LS5 5000 Watt Fiber Laser 6′ X 12′ Table

One of the latest additions to RiverCity Industries and another flagship machine is our 6′ X 12′ 5000 Watt Fiber laser. With the delivery of the cutting beam by fiber optic cable this machine provides much faster cutting speeds than your typical CO2 laser. The fiber delivery also allows for cutting of reflective materials such as copper & brass and thicker aluminum and stainless than a CO2 laser.

- Fiber Laser Cuts Problematic Alloys like Aluminum – Copper & Brass

- Faster Cutting Speeds on Carbon and Stainless Steel

- High Production – Table Shuttle System

Bystronic high production laser for cutting metal at high production quantities. This was our second high speed metal cutting laser, after we retired our Mazak – This high speed laser cutting machine allowed us to keep up with the demand from our Houston, San Antonio and Austin customers.

- 90 degree Cutting Head

- Dual Table Shuttle System

- High production

- Very little set up time

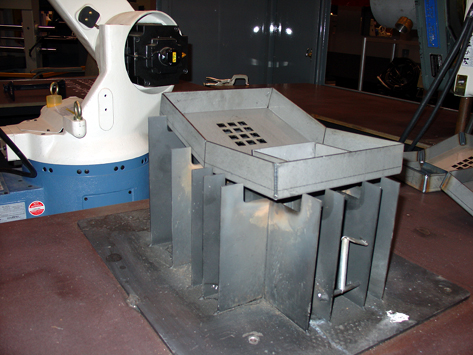

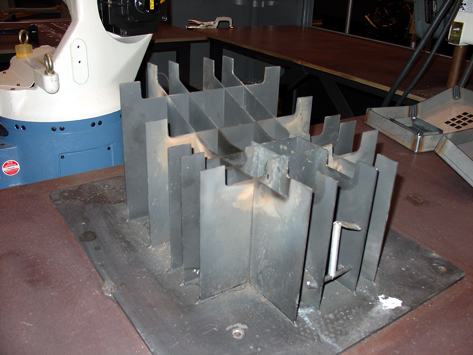

Have a difficult part you need to hold?

Let us make a Laser cut sheet metal workholding fixture. Our laser software will convert your CAD drawings into Laser cutting 3-D preformed fixtures.