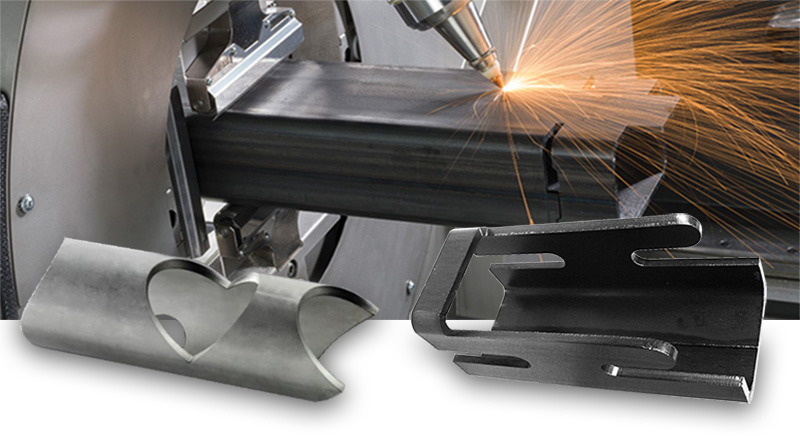

Tube Lasers Cut Saddle and Fish Mouth Coping Beautifully

- Saddle Cuts & Fish Mouth Coping

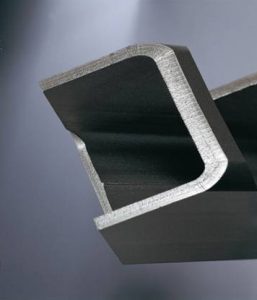

- Chamfering & Beveling

- Bundle Loading Tube Laser

- Laser cut chamfering, beveling for perfect weld fit-up on end forms

- Large capacity bundle loader – up to 27 foot long tubes. Laser head cuts up to 8.875″ diameter tube & 5/8″ wall thickness on smaller diameter tubing.

Note: Although the above are limits of the chuck capacity and thickness of the wall the laser can cut. Please note that we are also limited to 23.5 pounds per lineal foot, mainly because of the robotic bundle loading mechanisms. You can find the per lineal foot weight of any tubing by doing a Google search and looking at the charts from various tubing suppliers. Some examples of our laser tube cutting limitations are:

Round Tube & Pipe Laser Cut

- 4″ Round Tubing at 1/2″ Wall Thickness = YES

- 6″ Round Tubing at 3/8″ Wall thickness = YES

- 6″ Schedule 40 pipe = YES

- 6″ Schedule 80 pipe = NO

- 8″ Round Tubing at 1/4″ Wall Thickness = YES

- 8″ Schedule 40 Pipe = NO

Square Tube Laser Cut

- 4″ Square Tubing at 1/2″ Wall Thickness = YES

- 6″ Square Tubing at 1/4″ Wall Thickness = YES

- 6″ Square Tubing at 3/8″ Wall thickness = NO

Rectangle Tube Laser Cut

- 5″ x 3″ Rectangle Tube at 1/2″ Wall Thickness = YES

- 6″ x 3″ Rectangle Tubing at 3/8″ Wall thickness = YES

- 6′ x 3″ Rectangle Tubing at 1/2″ Wall thickness = NO

*Please call us for further details and to see if we can handle the tube size of your laser tube cutting project.

Our original Mazak 3D tube laser. She brought us to the dance. Still going strong after over 10 years of service. Our staff is experienced in the 3-D drafting and design – exactly what it takes to cut complex parts in 3D.

Over the years we have won over many jobs from machining processes. Cutting 3-D parts from “off the shelf” metal tubing in a fraction of the time and cost traditionally used by machining processes. Weather you need 3D cutting of square tube, round tube, triangular pipe, or C, H, I and L beams. The 8 axis torch and simultaneously controlled chuck cut all in one single operation – beautiful angle cuts, chamfers, weld-prep bevels and advanced, complex contours such as saddle joints and fish mouth cuts. Laser cutting produces less heat and greatly reduces any distortion. The bottom line – very little secondary machining needed – Crisp, clean edges – little Dross, reduced or eliminated Burring. Laser cut parts are ready to go. Tube Laser metal cutting for Texas and beyond.